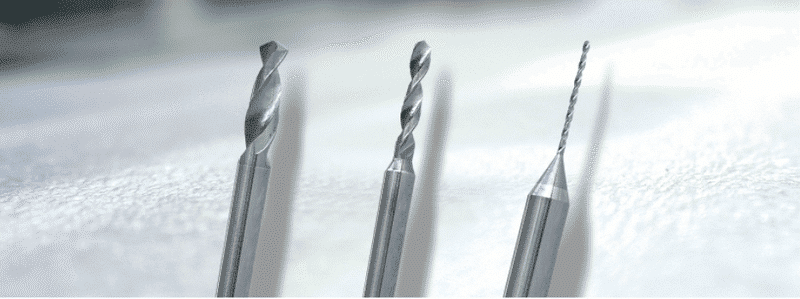

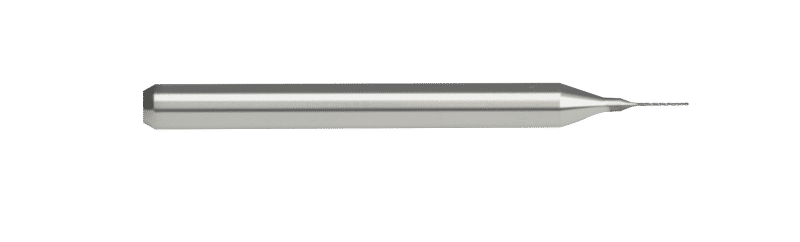

STANDARD DRILL SERISE(ST)

Standard ST-type drill bit, with excellent comprehensive performance, suitable for all kinds of sheet metal processing

Standard ST-type double-edged double groove drill

Good sharpness, fast chipping and low processing temperature.

For problems such as crimping, glue pulling in holes, wire drawing in holes, and hole burning.

Suitable for PCB ordinary TG, soft board, soft and hard board processing

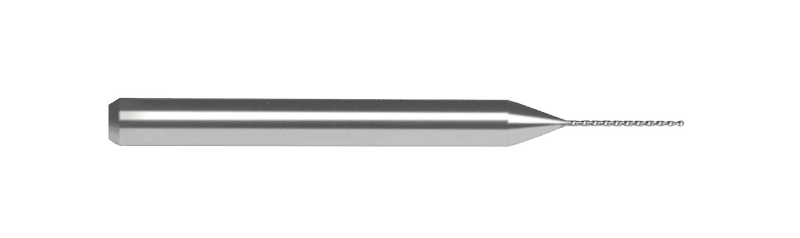

UC DRILL SERIES(UC)

UC type drill bit can reduce the friction between the drill bit and the hole wall.

Ensure good hole wall quality, suitable for processing various types of plates

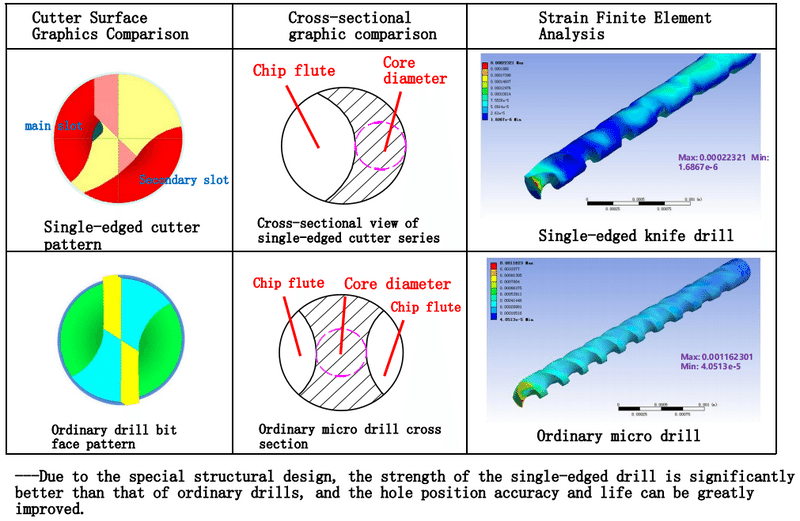

DR-UC type single-edge single groove drill

Strong rigidity, reduced yaw radian during drilling, and high positioning accuracy.

For problems such as partial hole 、broken knifeand wire wrapping .

Suitable for PCB high TG, thick copper, halogen-free, plate drilling processing

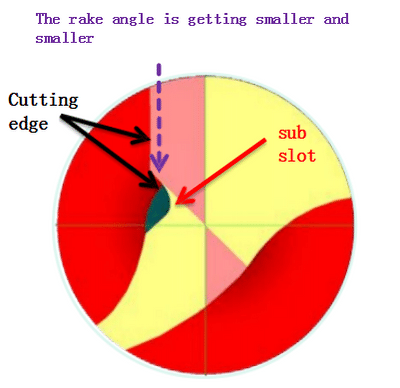

Sub groove design

The sub-groove design is aimed at the winding performance, knife breaking performance

and durabilityThe performance of CAF has been significantly improved, and the design features are as follows:

1. A unique broken-line cutting edge is formed, which increases the effective length of the main cutting edge

and improves chip breaking performance at the same time.

2. Increase the rake angle of the cutting edge near the center, so that the extrusion process at the

center becomes cutting processing, which improves the cutting performance.

3. The axial force of the drill is small, the positioning is more accurate, and the hole position accuracy can still be maintained

after the drill is ground (the core diameter gradient of the conventional drill is set, the core thickness becomes larger after grinding,

and the centering of the drill is not correct. Precise, large axial force, severe knife breakage will occur)

4. The cutting force is small during drilling, which can effectively improve the CAF problem caused by high cutting force.

Application advantage

Due to the unique design, the single-edged cutter has strong rigidity, excellent hole position accuracy, and its service life is

greatly improved compared with conventional drill bits. It can effectively solve the problem of high hole position requirements

and partial hole scrapping at the customer site, and provide solutions for customers to improve efficiency and reduce costs.

Lower costs• Obtained by using ordinary aluminum sheet instead of coated aluminum sheetSame hole position result, lower material cost

increase lifesp• . Under the same conditions, the life of single-edged cutter products is about 30% longer than that of conventional products.

increase efficiency•Using a single-edged knife drill, the cutting speed can increase the efficiency by about 10%, and the efficiency is high.

Compared with the conventional drill bit, it still meets the processing requirements after increasing the number of stacked plates.

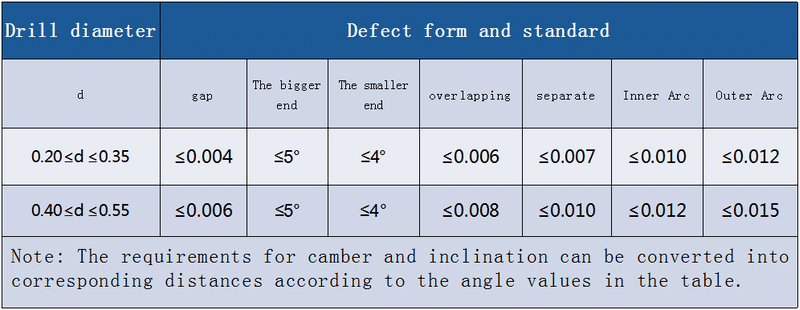

Testing Standard

Note: The standard refers to GB/T 28248-2012 "Cemented Carbide Drill Bits for Printing"

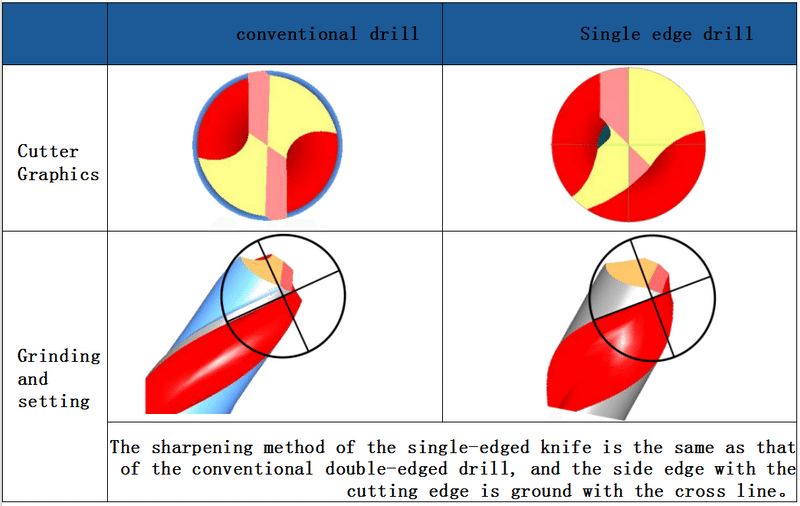

Grinding Method

UC type double-edged single groove drill

The unique design of the cutter head reduces the torque resistance of the drill, has strong rigidity,

reduces the deflection arc during the drill, and has high positioning accuracy.

For problems such as partial hole and broken knife.

Suitable for PCB high TG, high multi-layer, thick copper, halogen-free, plate drilling processing

UC type double-edged double groove drill

The unique cutter head design reduces the torque resistance of the drill, reduces the breakage rate,

and improves the chip removal performance.

Aiming at problems such as hole thickness, sharp edge, and wire wrapping in the hole.

Suitable for PCB high TG, high multi-layer plate drilling processing

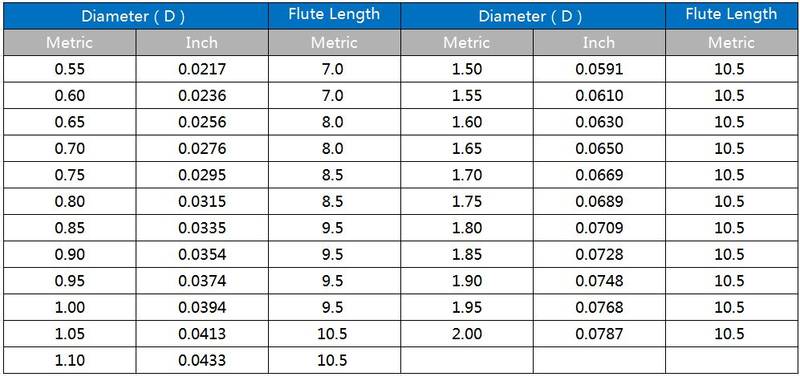

Product Technical Parameters